- Constant control and maintenance of the room temperature.

- Possibility of an integrated heat pump.

- Control via proprietary software.

- Compact and simple installation.

Air Handling Unit - A1

The A1 Series Air Handling Unit is the result of a continuous improvement process, thanks to the Research and Development activity that the company has been carrying out since its foundation. This product adapts perfectly to the needs and requests of different customers, and can be used in all sectors.

Adaptable

Thanks to the bespoke and personalized design, the A1 series is able to meet the most stringent requirements.

Reliable

The unit guarantees the highest levels of energy efficiency, and is characterized by a long life cycle associated with low maintenance costs.

Modular

The customizable modular design simplifies the operations of transport and installation in the field, reducing times and costs.

Features

Capacity

Variable from 500 m³/ h to 300.000 m³/ h

Dimensions

Completely personalized

Performance

Mechanical resistance class D1, air loss rate class L1, heat transmission class T1, thermal bridge factor class TB2

Conformity

Conformity to European regulations, EUROVENT certification. Available with services that comply with EU Regulation No. 1253/2014

Sectors and applications

Saiver's A1 unit is designed and built to meet all design, technical and dimensional requirements, while respecting the containment of noise levels, the quality of the air produced and the energy consumption. Taking into account all these characteristics, the product is able to cover all fields of application and economic sectors, configuring itself on the customer's requests

Hospital and clean rooms

Shopping, business and assembly centers

- Complete antibacterial and antiviral action.

- IAQ control.

- Control via proprietary software.

Industrial

- Humidity control and containment systems.

- Adjustments for noise control.

- Specific choice of materials.

Naval

- High design flexibility.

- Compliance with marine standards

- Easy installation and maintenance.

- Specific choice of materials.

Oil and gas

- Compliance with ATEX regulations.

- Specific choice of materials.

- High design flexibility.

Airport

- Control via proprietary software.

- Complete antibacterial and antiviral action.

- IAQ control.

Food

- Easy internal cleaning.

- Control via proprietary software.

- Complete antibacterial and antiviral action.

- Specific choice of materials.

Residential and hotels

- Control via proprietary software.

- Complete antibacterial and antiviral action.

- IAQ control.

Others

Components

Damper

Extruded aluminum blades with wing profile section, with sealing gasket, levers, with glass loaded nylon bushings. Combined control system: manual and prepared for servo motor. Model A160: class 2 - EN1751 Model A160H: class 3 - EN1751 Possibility class 4

Filter

Coarse dust: ISO class Cosare 30 ÷ 55% according to ISO 16890 (classification EN 779: 2012 G2 ÷ G4) Poor fine: ISO 16890 classification ePM101070%, ePM150% ÷ 85% (classification EN779: 2012 M6 ÷ F9) Absolute filtration (EPA, HEPA, ULPA): efficiency ≥85% ÷ 99.5 @ MPPS according to EN 1822: 2010 (EPA class E10 ÷ E12) integral efficiency ≥99.95% @ MPPS according to EN 1822: 2010 (HEPA class H13 ÷ H14) Activated carbon filters: Activated carbon filter for deodorization and chemical-physical adsorption of gaseous pollutants.

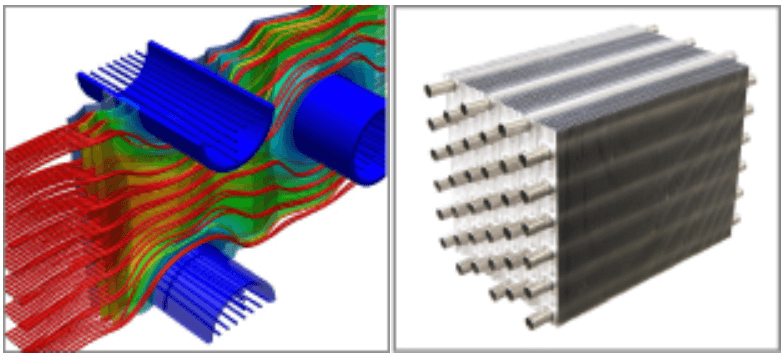

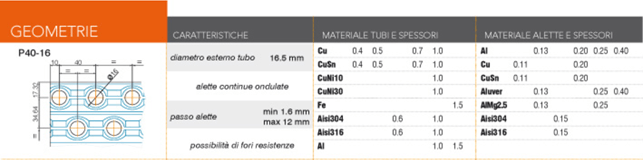

Batteries

Finned pack exchangers composed of mechanically expanded tubes inside self-spaced collars obtained on the fins that have undulations. It is composed of mechanically expanded tubes inside self-spacing collars obtained on the fins, which have undulations

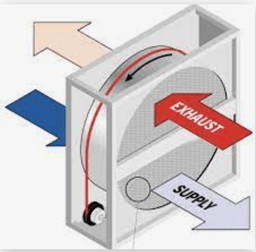

Heat recovery systems

Battery operated (sensitive), plate with cross flow (sensitive), rotating (latent).

Humidifiers

Isothermal steam humidifiers: Network steam distributors Immersed electrode steam humidifiers Resistance steam humidifiers Steam distribution systems Adiabatic humidifiers Evaporating pack humidifiers (cellulose or glass fiber) Nozzle washer with electro pump Compressed air and water humidifiers Pressurized water humidifiers Ultrasonic humidifiers

Fans

Centrifugal fans with transmission Directly coupled centrifugal fans Directly coupled fans Plug fan (plenum fans) EC fans with brushless technology

Basins

Basins inclined towards the drain. Made in aluminum alloy, in AISI 30e and 316.

Dehumidifier

The drying wheel eliminates the humidity present in the air because the material of which it is made retains the water vapor ensuring the control of humidity in industrial and pharmaceutical processes.